The Rubber roller is engineered to resist abrasion, ensuring long-lasting performance even in high-wear applications. This characteristic reduces the need for frequent maintenance and replacement, saving time and costs for industrial operations.

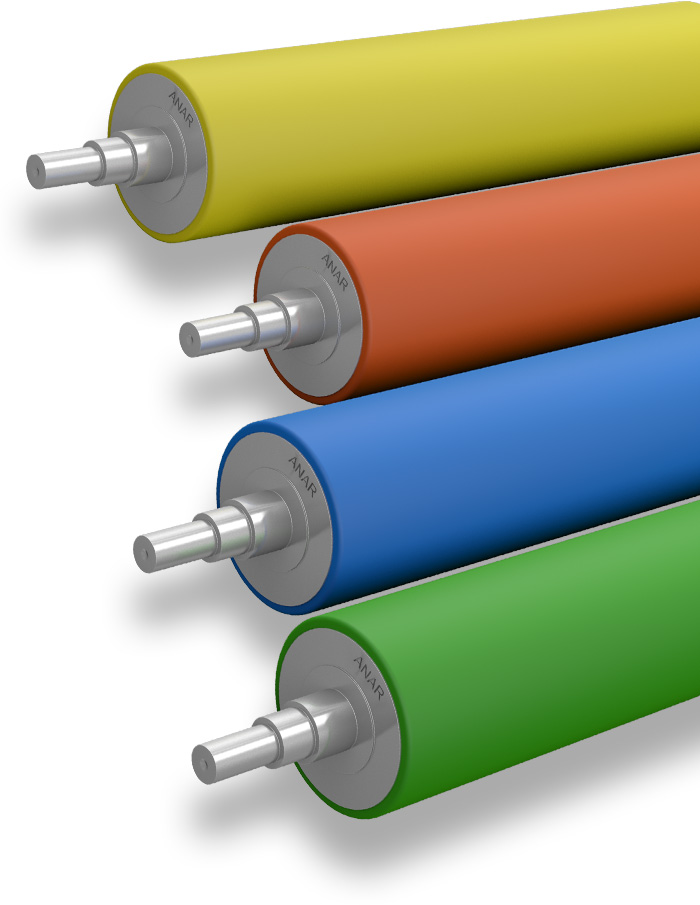

Rubber Roller

About Rubber Roller

Rubber Rollers Manufacturer

The Trusted Rubber Roller in India is manufactured mainly using high hydraulic pressure, which ensures a compact microstructure and longer service life and strength. The rubber roller we produce is designed to withstand even the toughest demands, such as temperature fluctuations or abrasives and solvents. We create customized solutions for various precise applications across different manufacturers. Our products are made with the latest technologies and innovative ideas. The industries we serve include printing, paper, plastic, packaging, and many others. Our mission is to provide our customers with the quality equipment they need to achieve the desired outcome as per their quality standards.

Our rubber rollers are specially designed to meet the finest requirements of applications in paper, textiles, plastic, and many other industries. It has proven its reliability time and time again in demanding environments. Rubber rolls manufactured at Anar Rub Tech Pvt Ltd. provide a wide range of advantages such as wear resistance, antistatic property, chemical resistance, heat resistance, non-stick surface, and friction resistance to our customers.

We understand the value of every minute, and that is why we are focused on offering fast quotes, competitive prices, and fast delivery times. As a leading rubber roller manufacturer, we have successfully responded to the expansion of several markets in India and abroad. With our extensive experience and knowledge, we have many OEM customers. This technical knowledge and deep understanding of track applications is the first priority for our customers. We know that we must be equally active in providing technical solutions rather than just making and selling the rolls.

Rubber Rollers for Diverse

Industry Applications

01. Industrial Rubber Roller

02. Printing Rubber Roller

03. Lamination Rubber Roller

04. Flexo Printing Rubber Roller

05. Silicone Rubber Roller

06. Solventless Rubber Roller

Anar Rub Tech Pvt Ltd is a leading industrial rubber roller manufacturer in Ahmedabad. Industrial rubber rolls are widely used for production in various fields. It is used in various industrial applications such as paper milling, textiles, printing, steel, packaging, plastic, processing, plywood, foam, etc. In addition, it is a highly finished, wear-resistant, and high-tensile industrial rubber roller that ensures an excellent finish.

Anar Rub Tech Pvt Ltd manufactures printing rubber roller with precise surface treatment and special rubber compound which gives the best result in today's modern printing industry. Printing rubber rollers are used in various printing machines such as flexo printing machines, gravure printing machines, label printing machines, etc. Our printing rolls are resistant to ink, ethyl, and toluene.

Anar Rub Tech Pvt Ltd offers quality lamination rubber roller for various lamination processes like Solvent less / Solvent Base lamination, hot lamination, cold lamination, etc. Anar only uses a special composition that gives consistently better result than usual market products. The laminated rubber roll offered by us is manufactured using high-quality materials and modern processes as per industrial requirements.

We have a long history of efficient manufacturing and supplying flexo printing rubber roller. These rollers are chemical-free and anti-static, durable with a super-finished surface that provides high performance. Our products are tested with various parameters before being sent to customers. These rollers are light and very friendly with various production technology in use by production houses.

Silicone rubber roller made by Anar Rub Tech Pvt. Ltd. is widely used in various applications such as lamination, coating, hot stamping, non-stick applications, etc. A silicone rubber roller is also used in the food industry and the food packaging industry. These rolls have amazing features like anti-static nature, high-temperature base, non-sticky and chemical resistance, good wear resistance, etc. Our rolls are manufactured under the guidance of our experienced professionals using high-quality raw materials and modern technology.

Anar Rub Tech Pvt Ltd is India's leading rubber rollers manufacturer. Our rollers are specially designed for the various industry, keeping the special requirements of their process. Our solventless rubber roller are made from high-quality raw materials using the latest technology. For the plastic and flexible packaging sector, we have a unique rubber compound for solvent-free laminate rolls. Our solvent-free laminate rubber rolls perform exceptionally well and are highly soluble and resistant to various harmful effects for food industry.

No.

Rollers Name

01.

Printing/Impression Furnishing Rollers.(Rotogravure, Flexographic Printing)

02.

Lamination Rollers(Solvent less / Solvent Base Lamination)

03.

Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

04.

Diamond Groove Rollers & Customized Groove Rollers.

05.

Drive Rollers

06.

Guide Rollers

07.

Grooved Rollers

08.

Conveyor Rollers

09.

Dead Shaft Rollers

No.

Rollers Name

01.

Core Roller Manufacturing

02.

Rubber Coating

03.

Rubber Grinding & Finishing

04.

Inspection

Specifications

Specifications detail material, dimensions, hardness, and performance for various industrial needs.

No.

Material

Dimensions

01.

Shell Material

02.

Diameter

03.

Length

04.

Coating

Key Features of

Our Rubber Rollers

Features

High-Quality Rubber

Our rubber rollers are made from premium rubber compounds for superior durability and performance.

Precision Machining

Each roller undergoes precision machining to ensure uniform diameter and smooth surface finish, reducing friction and wear.

Dynamic Balancing

Our rollers are dynamically balanced to minimize vibration and ensure smooth operation at high speeds.

Chemical Resistance

The rubber compounds used in our rollers are resistant to chemicals, oils, and solvents, ensuring long-term reliability in various industrial environments.

Heat Resistance

Our rollers can withstand high temperatures, making them suitable for applications where heat is a factor.

Customizable Options

We offer a variety of customization options, including different rubber compounds, hardness levels, and roller dimensions, to meet specific customer requirements.

Advantages Advantages of Rubber Roller

These rolls offer several advantages to their customers. Unlike metal rollers in transport systems, rubber rolls are characterized by the highest coefficient of friction, which enables good adhesion of moving components and parts. In addition, they can adapt to small changes resulting from the operation of machines. In addition, they have all the advantages of rubber. These rolls offer several advantages to their customers. Unlike metal rollers in transport systems, rubber rolls are characterized by the highest coefficient of friction, which enables good adhesion of moving components and parts. In addition, they can adapt to small changes resulting from the operation of machines. In addition, they have all the advantages of rubber.

The reason why rubber is a very popular material for creating rollers and moving things is that it can be repeatedly compressed and released without losing its original shape. A material that cannot maintain its shape and needs constant replacement can be completely ineffective for manufacturing processes. More so, rubber can absorb shocks, scratches, and injuries too making it one of the finest materials for industrial requirements. It is also relatively cheap to acquire and handle, offering a competitive price advantage. Another very big advantage of these rollers is that they can be recycled and used again and again, which supports the current scenario, which requires support for the ecosystem.