Anilox rollers are coated with a ceramic layer to ensure precise ink transfer and uniform coverage on various substrates. This coating is highly wear-resistant, prolonging the life of the roller and maintaining consistent print quality over time.

Anilox Roller Manufacturer

About Anilox Roller

High-Quality Anilox Roller superior grip on materials

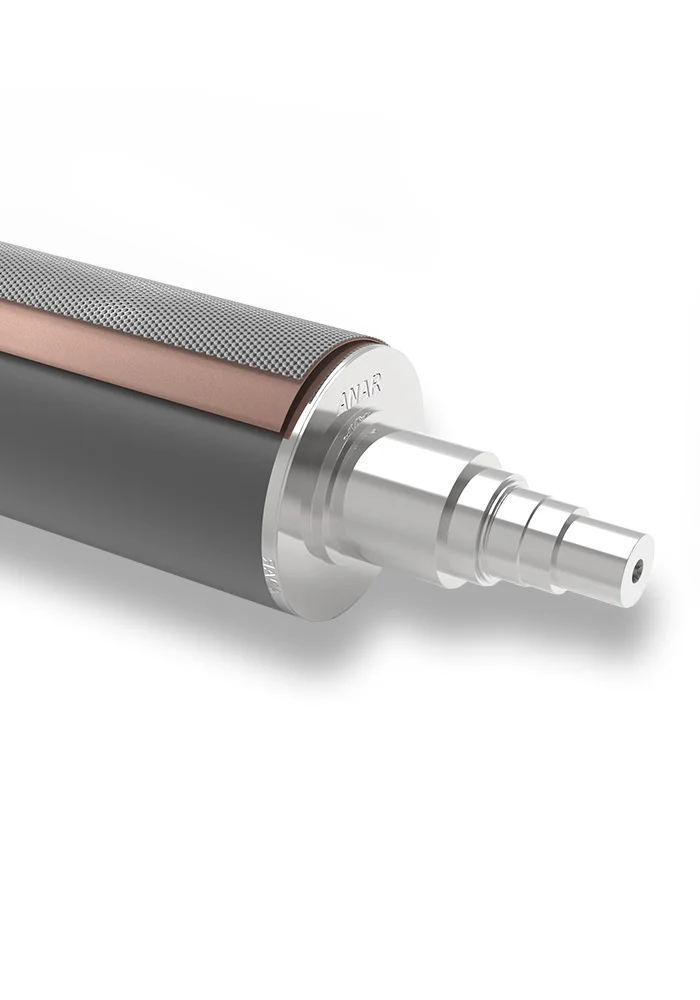

Anilox rollers are crucial components in the printing industry, specifically in flexography and offset printing. These rollers are responsible for transferring a precise and consistent amount of ink to the printing plate. Anilox rollers are typically made of steel or ceramic and are characterized by their unique cell structure, which determines the amount of ink delivered to the plate. The cell structure is measured in lines per inch (LPI), with higher LPI indicating finer cells and thus more detailed printing capabilities.

One of the key features of anilox rollers is their ability to control ink volume. The cell structure, combined with ink viscosity, determines the ink deposited on the plate. This control is essential for high-quality prints with accurate color reproduction and consistent ink coverage. Anilox rollers are available in various configurations to meet printing requirements, from standard to high volume and specialized applications. Anilox Roller Manufacturer in Ahmedabad, Gujarat, India, supply these precision components to the printing industry.

Maintaining anilox rollers is essential for ensuring optimal performance and longevity. Regular cleaning is necessary to prevent ink buildup and maintain the integrity of the cell structure. Various cleaning methods are available, including mechanical cleaning with brushes or blades, chemical cleaning with solvents, and ultrasonic cleaning.

01. Precision Engraving for High-Quality Printing

02. Advanced Ceramic Coating for Longevity and Performance

Anilox rollers are essential components in the printing industry, known for their ability to deliver precise and consistent ink transfer to printing plates. These rollers are characterized by their engraved surface, which contains millions of tiny cells or "anilox cells." The size and shape of these cells determine the amount of ink transferred to the printing substrate, making anilox rollers crucial for achieving high-quality prints. Additionally, the cell geometry plays a significant role in controlling ink film thickness and distribution, ensuring uniformity across the printed material.

Anilox rollers are often coated with advanced ceramic materials to enhance their durability and performance. Ceramic coatings offer exceptional wear resistance, ensuring that the engraved cells maintain their shape and size over prolonged use. This not only extends the lifespan of the roller but also ensures consistent print quality throughout its service life. Furthermore, ceramic coatings can be engineered to provide specific surface properties, such as improved ink release and easy cleaning, further enhancing the efficiency and reliability of anilox rollers in printing applications.

Key Features

Features

Cell Geometry

Anilox rollers from Anar Rub Tech Pvt. Ltd. feature precisely engineered cell geometries to ensure consistent and controlled ink transfer.

Line Screen

With high line screens, Anar Rub Tech Pvt. Ltd.'s Anilox rollers offer exceptional printing detail and resolution.

Volume Control

The Anilox rollers are designed to provide accurate and uniform ink volume control.

Surface Finish

Anar Rub Tech Pvt. Ltd.'s Anilox rollers are known for their ultra-smooth surface finish.

Material Composition

These rollers are constructed using high-quality materials that offer durability and long service life.

Dynamic Balancing

Anar Rub Tech Pvt. Ltd. ensures that their Anilox rollers are dynamically balanced to perfection.

Advantages of Anilox roller

Anar Rub Tech Pvt. Ltd. is a trusted name in the industry, known for its commitment to quality and customer satisfaction. The company's Anilox rollers are crafted with precision and expertise, ensuring optimal performance and longevity. Anar Rub Tech Pvt. Ltd. offers a wide range of Anilox rollers, each designed to meet specific printing requirements. Whether you need high line screens for fine detail or precise volume control for uniform ink distribution, Anar Rub Tech Pvt. Ltd. has the perfect solution.

Moreover, Anar Rub Tech Pvt. Ltd. provides exceptional customer support, guiding clients through the selection process and offering expert advice on installation and maintenance. Their dedication to customer satisfaction sets them apart from other manufacturers in the market.

Additionally, Anar Rub Tech Pvt. Ltd. is known for its innovative approach to Anilox roller design, constantly seeking ways to improve performance and efficiency. By choosing Anar Rub Tech Pvt. Ltd. for your Anilox rollers, you can rest assured that you are investing in a high-quality product backed by years of industry experience. Their commitment to excellence and customer satisfaction makes them the preferred choice for printers and converters worldwide.